Numbers for mild or low alloy steel electrodes begin with an 'E' prefix (meaning 'electrode') followed by a four or five-digit number in most cases. Rods come in sizes from 1/16 to 5/16, so a typical number would indicate a 1/8 inch E10011 rod.

After reading this you will learn about Electrode:- 1. Meaning of Electrode 2. Heavy-Coated Electrodes 3. Coating Functions of Electrode 4. Specification of Electrodes 5. Electrode Coating 6. Types of Coated Electrode 7. Core Wire Materials (Electrode) 8. Use of Electrodes in Industry 9. Damaged Electrodes should not be used 10. Effect of Moisture on Electrode and Its Storage.

Meaning of Electrode:

E7018-A1 DATA SHEET Pinnacle Alloys E7018-A1 AWS CLASS E7018-A1 H4R CODE AND SPECIFICATION DATA: AWS A5.5 ASME SFA 5.5; UNS W17018 DESCRIPTION: Pinnacle Alloys E7018-A1 electrodes are similar to E7018 carbon steel electrodes classified in AWS A5.1/A5.1M, except that 0.5% molybdenum has been added. This addition increases the. RE: Welding E7010/8010 versur E7018 stanweld (Materials) 3 Jan 07 17:11 Due to its 'fast freeze' characteristics, availability in smaller diameters and lower operating amperage range, the EXX10 electrode has a distinct advantage over EXX18 electrodes when welding steel sheet materials, whether coated or not. E7018 Welding Electrode is an outstanding quality all position welding electrode, covered with extra low hydrogen potassium type, coating for welding high tensile steels and low alloy steels. Its nominal welding efficiency is about 110% due to iron powder is contained. MILD STEEL COATED ELECTRODES E7018-X EIndicates that this is an electrode 70Indicates how strong this electrode is when welded. Measured in thousands of pounds per square inch. 1Indicates in what welding positions it can be used.

An electrode consists of a metal core wire with an insulating covering (flux-coated). In metal arc welding the electrodes used are metal and carbon in a cut-piece (stick electrode) rod of definite length and diameter while Automatic and Semi-automatic welding electrodes use bare wire in coils.

The manual arc welding (MMAW) or SMAW (Stick metal arc welding) process uses consumable flux-coated electrodes to produce heat by arcing as well as to supply filler material to weld zone. Metal and carbon electrodes are mainly used in manual welding in steel, alloy-steel, structural steels, heat-resistant steel, surfacing (build-up metal), cast-iron, mild steel, and other metal alloys.

ADVERTISEMENTS:

Metal electrodes are of three types:

(1) Bare electrode;

(2) Coated electrode; and

(3) Heavy coated electrode.

Bare electrodes have a limited use for welding of wrought iron and mild steel. In use of bare electrode, as the globules of metal pass from the electrode to the work, they are exposed to the oxygen and nitrogen in the surrounding air and thus decreases the strength and ductility of the metal.

If a bare wire is used as the electrode it is found that the arc is difficult to control, the arc stream wandering over the molten pool. The result is that the weld tends to be porous and brittle. With bare wire electrodes, much metal is lost by volatilisation—turning into a vapour.

7018 Electrode

On the other hand, covered electrodes reduce the loss Coated electrodes have many advantages. A coated electrode is a carbon steel filler rod that has been covered by same form of fluxing material. The coating compositions are applied around a wire to stabilise the arc and improve the properties of the weld metal.

Material in electrode coating for positional weld are mainly Borax, Ammonia, Sulphur, Cellulose, Calcium Carbide, Dolomite, Rutile, Mica, Clay, Silica, Manganese Dioxide, Iron Powder, Ferro-Silicon, Sodium Silicate, Potassium Silicate, etc. Fig. 6.1 shows some coated electrode.

These are all deoxidizing agents. The coating applied to the electrode wire largely determines the resultant weld metal's strength. The arc can be rendered easy to control and the absorption of atmospheric gases are reduced to a minimum by ‘Shielding' the arc.

Under the heat of the arc, chemical compounds in the electrode covering also react to form a slag which is liquid and lighter than the molten metal. It rises to the surface, cools and solidifies, forming a protective covering over the hot metal while cooling and protecting it from the atmospheric effects of the weld metal.

The electrode covering usually melts at a higher temperature than the wire core so that it extends a little beyond the core and directing the arc stream, making the arc stable and easier to control.

Heavy-Coated Electrodes:

Heavy-coated electrodes or shielded arc electrodes are used to obtain a weld metal of high quality, comparable with—and even superior to—the parent metal in terms of mechanical properties. Industrial manufacturers produce a large variety of heavy-coated electrodes developed by various research establishments and industrial laboratories.

ADVERTISEMENTS:

The coatings of welding electrodes serve several purposes:

(1) Facilitate the establishment and maintenance of the arc;

(2) Protect the molten metal from the oxygen and nitrogen of the air by producing a shield of gas around the arc and weld pool;

(3) Provide a slag blanket on the weld so as to reduce the rate of cooling;

(4) Provide a means of introducing alloying elements not contained in the core wire.

Before preparation of the coating the core wire consists in cleaning, cutting, and straightening the wire. The wire is cleaned of dirt and grease by washing it in hot water containing 5 per cent soda ash. It is then cut and straightened in machines at a rate up to 300 electrodes per minute. Then the cut pieces are dried by heating to 80°C-90°C, the bare rods are sorted and stored in a dry room.

Electrodes with a dip coating are dried either in the air or in well-ventilated rooms at room temperature (70°F/21°C) for 12-20 hours until the coating finally solidifies. Coated electrodes are roasted in pot furnaces and ventilated in drying ovens or electric-heated cabinets.

Coating Functions of Electrode:

(1) Stabilise the arc;

ADVERTISEMENTS:

(2) Provide a protecting atmosphere or prevent oxidation;

(3) Remove oxides and impurities;

(4) Influence the shape of bead;

(5) Control the melting rate;

(6) Forms a slag over the weld;

(7) Smooth out the wave formation or welding ripple on the surface of the weld profile.

Specification of Electrodes:

It is very much necessary to know about the specification of electrodes and their application in industries. Electrodes know have to be selected as per thickness of metals, nature of jobs, materials to be welded and after that, the amps adjusted for welding. In a large scale, electrodes are used in Welding Technology. A good selection of electrodes makes a good joint.

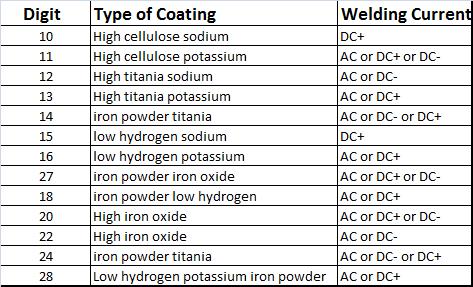

Attached table gives the details:

Coating compositions which have been developed to accomplish these results may be classified as organic and inorganic. Inorganic coatings can be further subdivided into flux compounds and slag-forming compounds (Fig. 6.1 shows the types of electrodes). These three elements, i.e., size, type, and current, which are already mentioned above are the primary factors of determining the fusion time.

ADVERTISEMENTS:

Once having determined the fusion time the usual procedures are much as the literature on the subject i.e., to multiply this time by a factor depending upon the type of weld, the position of weld, the type of work, etc. This factor is termed as duty cycle and is used to cover all of the ancillary elements too varied to assess in detail.

Next, the welding elements of time usually associated as being factors of the fusion time and bearing some direct relationship to the weld deposition rates are:

(1) The efficiency of electrode fusion time;

(2) The changing of the electrode;

(3) De-slagging;

(4) Inspection;

(5) Weld volume;

(6) Reinforcement;

(7) Perfection;

(8) Relaxation; personal allowance.

These factors can be said to be a direct part of the welding cycle.

Electrode Coating:

ADVERTISEMENTS:

It is a material applied around a wire to stabilise the arc and improve the properties of the weld metal.

Material in electrode coating for positional weld are mainly Borux, Ammonia, Sulphur, Cellulose, Calcium carbide, Fluorspar, Dolomite, Rutile, Feldspar, Mica, Clay, Silica, Manganese dioxide, Iron oxide, Iron powder, Ferro-silicon, Ferro-manganese, Sodium silicate, Potassium silicate, etc. All these are known as de-oxidising agents.

Types of Coated Electrode:

A. Mild Steel (Industrial Standard: IS-2825):

(1) Cellulosic

(2) Rutile

(3) Iron powder

(4) Low hydrogen

(5) Low hydrogen low alloyed

(6) Hard facing

B. Stainless Steel Condition Weld:

C. Cast-iron:

ADVERTISEMENTS:

(1) Machinable (Pure nickel covered)

(2) Non-machinable—Monel (70% Ni; 30% Copper)

(3) Non-machinable—Ferro-Nickel (Ni 55%; Fe 45%)

D. Inconel Electrode—Nickel type.

Functions of Coating:

The coating performs the following functions:

1. Provides a protecting atmosphere, i.e., prevent oxidation.

2. Stabilizes the arc.

3. Removes oxides and impurities.

4. Influences the shape of the bead.

5. Speeds up the process by increasing the melting rate or control melting rate.

6. Facilitates overhead and position of welding.

7. Forms a slag over the weld. The slag

(a) Protects the molten metal from contamination by the arc.

(b) Reduces the rate of coating of the weld.

(c) Smooth's out the wave formation or welding ripple on the surface of the weld.

Protection of the Weld Metal:

The coating applied to the electrode wire largely determines the resultant weld-metal quality.

There are two distinct types of protection:

First, there is the formation of a fusible slag. If this was ideal it would coat every globule of the weld metal with a skin which is impermeable to the atmospheric elements.

Secondly, there is the use of a chemically reducing gaseous envelope, which completely surrounds the arc. If the slag is not of a suitable chemical type, there may be chemical reaction of the slag in contact with the weld metal to the detriment of the latter. The electrode coating is consumed in the arc at a slower rate than the rate of deposition of the electrode metal.

As a result, the coating extends beyond the metal core of the electrode and serves to direct and concentrate the arc stream. The action of the arc on the coating of the electrode results in a slag formation which floats on top of the molten weld metal and protects it from the surrounding atmosphere while cooling.

N.B. S.W.G. means Standard Wire Gauge, measurement of Core diameter of an electrode.

Classification of Electrode:

In coating it consists of ‘PREFIX' letters and ‘SUFFIX' letters.

Prefix Letters:

‘A' and ‘M' used for ‘A' semi-automatic or automatic welding and ‘M' for manual metal – arc welding.

Suffix Letters:

‘H', T, ‘K', ‘P'

‘H' — Hydrogen Control.

‘J' — Iron powder covering giving a metal recovery of 110% to 130% inclusive.

‘K' — Iron powder covering metal recovery of over 130%.

‘P' — For deep penetration.

Code Number (Electrode):

1. 1st Digit Type of covering.

2. 2nd ' Welding position.

3. 3rd ' Welding current condition.

4. 4th Digit Tensile strength of the deposited metal.

5. 5th ' Percentage of elongation in tensile test of deposited metal.

6. 6th ' Inspect value of deposited metal.

Type of Covering:

Type 1:

This type of covering contains at least 50% cellulosic material. This class of electrode is characterised by deeply penetrated and rapid burn-off rate.

Type 6:

Low Hydrogen Electrode:

This type of electrode is sometimes referred to as 'Lime Ferric', Lime Fluorspar, Ferric, Basic type. The weld metal has a high resistance to hot and cold cracking and is less sensitive to variation in plate quality than that of other electrode.

The electrodes are particularly suitable for welding high tensile structure steels where the highest physical properties are required. They are also used for welding steels having higher carbon and sulphur contents than found in normal structural steels and for welding steels of unknown composition. When using these electrodes for welding it is necessary to use a short arc to achieve maximum soundness in the weld deposit.

Deep Penetration Electrode:

In the coating for an electrode the ‘suffix' letter ‘P' is used if the electrode has been manufactured to comply with the test requirements for deep penetration electrodes as specified in IS 814- 1963.

An electrode coated as a deep penetration electrode implies that the electrode is suitable for deep penetration Butt welding in the Flat position and for deep penetration Fillet welding in the Flat and Horizontal-Vertical position.

Core Wire Materials (Electrode):

Core wire materials are made of different contents of elements. Standard specifies the wire gauges, technical conditions, acceptance rules, test methods, packing and marking. The standard provides approximately 50 to 100 types of welding wire.

Electrodes for manual and automatic arc welding of low carbon, medium carbon, and low- alloy steels are mostly made of wire, contain not more than 0.1 per cent carbon and 0.35 to 0.6 per cent manganese. Some contain more manganese and both manganese and silicon.

Excess silicon in welding wire results in heavy sputtering and gassing in weld pool.

Welding Rod 7018 Meaning

Carbon welding wire also contains Chromium up to 0.2 per cent and Nickel not more than 0.3 per cent.

The content of sulphur and phosphorus—both are harmful impurities.

Electrodes are manufactured by the following operations:

(1) Preparation of core wire.

(2) Preparation of coating ingredients.

(3) Proportioning.

(4) Application of the coating.

(5) Drying of coated electrodes.

(6) Quality of inspection of coated electrodes.

(7) Grading and packing.

Electrodes are issued with certificates (I.S.I.) stating the name of the manufacturer, electrode classification type and size, number of the batch, core wire grade, number of the standard or chemical analysis of core wire, date of the manufacture, and test results etc.

Quality control in electrode making manufactures have to check their proportioning and mixing, application procedures, moisture content, and drying conditions. Moreover, the chemical analysis of the core wire is determined, the coating thickness is measured, and the electrodes are tested on trial plates.

Finished coated electrodes are sorted, wrapped in waxed paper, and bulk packed in wooden boxes. Before packing, the wire (core) ends of electrodes are painted by international colours for identification.

Use of Electrodes in Industry:

Different types of electrodes are used in different metals such as Cast-iron; Mild Steel; Steel; Carbon Steel; High Carbon Steel; Stainless Steel, etc.

In modern welding practice, some non-ferrous metals can be welded by arc system. For this purpose some special types of electrodes are used in Brazing, Brass welding and Aluminium and its alloy welding.

Nowadays we can easily weld two different metals. This is called dissimilar metal welding. A part of cast-iron can be welded with a mild steel. This type of electrode is made of both metals. It is very costly to weld.

In general purpose, electrodes are used in industries for a welding in medium and heavy structural works, Ship-building industries, Rail wagon, Oil storage tanks, Boilers, Bridges, Cranes, Pipelines, Coach-shells, and general fabrications.

Damaged Electrodes should not be used:

1. Always keep electrodes in a dry-oven or dry place.

2. Coating-less electrode makes ‘air-pocket' (Blow hole) in the welding zone which is a defect of welding.

3. Use and burn these damaged electrodes in rough work but not in welding.

Don't bend the Electrodes:

Often some welders or trainees bend the electrodes for ease of work—to shorten the length; THIS IS WRONG! Discredit to welders or trainees. The coating of the electrodes damage due to bending.

Always avoid Damaged Electrode:

Often some welders use coating-damaged electrode. They should avoid those electrodes. It is harmful on the part of welding strength. Here is a damaged electrode which was used by some welders.

Effect of Moisture on Electrode and Its Storage:

Moisture is watery particles of substance which floats in the air. This moisture often affects electrodes. Due to electrodes kept over prolonged periods in moisture condition the coating peels off; but when the atmosphere is humid the moisture gets deposited in the moisture of the coating of the electrodes.

Flux contents are not hygroscopic and render electrodes useless. When electrode remains in a moisture condition over a long period the water lodged in the pores of the coating causes the wire to rust. This rust starts spreading out—such electrode will not give a steady 'arc' and smooth weld.

Storage of Electrodes to Avoid Moisture:

Arc welding electrodes require special care in handling and storage to ensure that the flux coating may retain its original strength of landing over a long period and gives satisfactory welds in use.

(1) In rainy season, when storage rooms are expected to be very humid it is advisable to heat up and maintain the room temperature at least 10°C to 20°C higher than the outside temperature.

E7018 Welding Rod

(2) The moisture is driven out when the atmospheric humidity falls if the storage room is heated.

Don't Waste Electrodes:

The most valuable thing on the part of Industry which are used in factories and Training Centres.

LOOK! This is a new Electrode (Fig. 6.4).

Here is a burnt electrode, which often has been seen to thrown on the floor by welders.

This Is Wrong:

(a) A disgrace to the welders.

(b) A great loss of industry.

(c) A loss of profit-sharing bonus.

(d) A great loss of production.

And This Is Correct:

(a) A credit to the welders.

(b) More production and more profit bonus.

Type of Covering:

Type 1:

This type of covering contains at least 50% cellulosic material. This class of electrode is characterised by deeply penetrated and rapid burn-off rate.

Type 6:

Low Hydrogen Electrode:

This type of electrode is sometimes referred to as 'Lime Ferric', Lime Fluorspar, Ferric, Basic type. The weld metal has a high resistance to hot and cold cracking and is less sensitive to variation in plate quality than that of other electrode.

The electrodes are particularly suitable for welding high tensile structure steels where the highest physical properties are required. They are also used for welding steels having higher carbon and sulphur contents than found in normal structural steels and for welding steels of unknown composition. When using these electrodes for welding it is necessary to use a short arc to achieve maximum soundness in the weld deposit.

Deep Penetration Electrode:

In the coating for an electrode the ‘suffix' letter ‘P' is used if the electrode has been manufactured to comply with the test requirements for deep penetration electrodes as specified in IS 814- 1963.

An electrode coated as a deep penetration electrode implies that the electrode is suitable for deep penetration Butt welding in the Flat position and for deep penetration Fillet welding in the Flat and Horizontal-Vertical position.

Core Wire Materials (Electrode):

Core wire materials are made of different contents of elements. Standard specifies the wire gauges, technical conditions, acceptance rules, test methods, packing and marking. The standard provides approximately 50 to 100 types of welding wire.

Electrodes for manual and automatic arc welding of low carbon, medium carbon, and low- alloy steels are mostly made of wire, contain not more than 0.1 per cent carbon and 0.35 to 0.6 per cent manganese. Some contain more manganese and both manganese and silicon.

Excess silicon in welding wire results in heavy sputtering and gassing in weld pool.

Welding Rod 7018 Meaning

Carbon welding wire also contains Chromium up to 0.2 per cent and Nickel not more than 0.3 per cent.

The content of sulphur and phosphorus—both are harmful impurities.

Electrodes are manufactured by the following operations:

(1) Preparation of core wire.

(2) Preparation of coating ingredients.

(3) Proportioning.

(4) Application of the coating.

(5) Drying of coated electrodes.

(6) Quality of inspection of coated electrodes.

(7) Grading and packing.

Electrodes are issued with certificates (I.S.I.) stating the name of the manufacturer, electrode classification type and size, number of the batch, core wire grade, number of the standard or chemical analysis of core wire, date of the manufacture, and test results etc.

Quality control in electrode making manufactures have to check their proportioning and mixing, application procedures, moisture content, and drying conditions. Moreover, the chemical analysis of the core wire is determined, the coating thickness is measured, and the electrodes are tested on trial plates.

Finished coated electrodes are sorted, wrapped in waxed paper, and bulk packed in wooden boxes. Before packing, the wire (core) ends of electrodes are painted by international colours for identification.

Use of Electrodes in Industry:

Different types of electrodes are used in different metals such as Cast-iron; Mild Steel; Steel; Carbon Steel; High Carbon Steel; Stainless Steel, etc.

In modern welding practice, some non-ferrous metals can be welded by arc system. For this purpose some special types of electrodes are used in Brazing, Brass welding and Aluminium and its alloy welding.

Nowadays we can easily weld two different metals. This is called dissimilar metal welding. A part of cast-iron can be welded with a mild steel. This type of electrode is made of both metals. It is very costly to weld.

In general purpose, electrodes are used in industries for a welding in medium and heavy structural works, Ship-building industries, Rail wagon, Oil storage tanks, Boilers, Bridges, Cranes, Pipelines, Coach-shells, and general fabrications.

Damaged Electrodes should not be used:

1. Always keep electrodes in a dry-oven or dry place.

2. Coating-less electrode makes ‘air-pocket' (Blow hole) in the welding zone which is a defect of welding.

3. Use and burn these damaged electrodes in rough work but not in welding.

Don't bend the Electrodes:

Often some welders or trainees bend the electrodes for ease of work—to shorten the length; THIS IS WRONG! Discredit to welders or trainees. The coating of the electrodes damage due to bending.

Always avoid Damaged Electrode:

Often some welders use coating-damaged electrode. They should avoid those electrodes. It is harmful on the part of welding strength. Here is a damaged electrode which was used by some welders.

Effect of Moisture on Electrode and Its Storage:

Moisture is watery particles of substance which floats in the air. This moisture often affects electrodes. Due to electrodes kept over prolonged periods in moisture condition the coating peels off; but when the atmosphere is humid the moisture gets deposited in the moisture of the coating of the electrodes.

Flux contents are not hygroscopic and render electrodes useless. When electrode remains in a moisture condition over a long period the water lodged in the pores of the coating causes the wire to rust. This rust starts spreading out—such electrode will not give a steady 'arc' and smooth weld.

Storage of Electrodes to Avoid Moisture:

Arc welding electrodes require special care in handling and storage to ensure that the flux coating may retain its original strength of landing over a long period and gives satisfactory welds in use.

(1) In rainy season, when storage rooms are expected to be very humid it is advisable to heat up and maintain the room temperature at least 10°C to 20°C higher than the outside temperature.

E7018 Welding Rod

(2) The moisture is driven out when the atmospheric humidity falls if the storage room is heated.

Don't Waste Electrodes:

The most valuable thing on the part of Industry which are used in factories and Training Centres.

LOOK! This is a new Electrode (Fig. 6.4).

Here is a burnt electrode, which often has been seen to thrown on the floor by welders.

This Is Wrong:

(a) A disgrace to the welders.

(b) A great loss of industry.

(c) A loss of profit-sharing bonus.

(d) A great loss of production.

And This Is Correct:

(a) A credit to the welders.

(b) More production and more profit bonus.

(c) It helps the growth of industry.

Aws E7018

(d) Less time lost in changing electrodes.

(e) And your skill is your credit.

Related Articles:

ASME has adopted their own designation for welding processes, which are very different from the ISO definitions adopted by EN24063.

| Designation | Description |

| OFW | Oxyfuel Gas Welding |

| SMAW | Shielded Metal Arc Welding (MMA) |

| SAW | Submerged Arc Welding |

| GMAW | Gas Metal Arc Welding (MIG/MAG) |

| FCAW | Flux Cored Wire |

| GTAW | Gas Tungsten Arc Welding (TIG) |

| PAW | Plasma Arc Welding |

Straight polarity = Electrode -ve

Reverse polarity = Electrode +ve

| F Number | General Description |

| 1 | Heavy rutile coated iron powder electrodes :- A5.1 : E7024 |

| 2 | Most Rutile consumables such as :- A5.1 : E6013 |

| 3 | Cellulosic electrodes such as :- A5.1 : E6011 |

| 4 | Basic coated electrodes such as : A5.1 : E7016 and E7018 |

| 5 | High alloy austenitic stainless steel and duplex :- A5.4 : E316L-16 |

| 6 | Any steel solid or cored wire (with flux or metal) |

| 2X | Aluminium and its alloys |

| 3X | Copper and its alloys |

| 4X | Nickel alloys |

| 5X | Titanium |

| 6X | Zirconium |

| 7X | Hard Facing Overlay |

These refer to the chemical analysis of the deposited weld and not the parent material. They only apply to welding procedures in steel materials.

| A1 | Plain unalloyed carbon manganese steels. |

| A2 to A4 | Low alloy steels containing Moly and Chrome Moly |

| A8 | Austenitic stainless steels such as type 316. |

ASME Welding Positions Graphic Representation

Note the welding progression, (vertically upwards or downwards), must always be stated and it is an essential variable for both procedures and performance qualifications.

Welding Positions For Groove welds:-| Welding Position | Test Position | ISO and EN |

| Flat | 1G | PA |

| Horizontal | 2G | PC |

| Vertical Upwards Progression | 3G | PF |

| Vertical Downwards Progression | 3G | PG |

| Overhead | 4G | PE |

| Pipe Fixed Horizontal | 5G | PF |

| Pipe Fixed @ 45 degrees Upwards | 6G | HL045 |

| Pipe Fixed @ 45 degrees Downwards | 6G | JL045 |

| Welding Position | Test Position | ISO and EN |

| Flat (Weld flat joint at 45 degrees) | 1F | PA |

| Horizontal | 2F | PB |

| Horizontal Rotated | 2FR | PB |

| Vertical Upwards Progression | 3F | PF |

| Vertical Downwards Progression | 3F | PG |

| Overhead | 4F | PD |

| Pipe Fixed Horizontal | 5F | PF |

Welding Positions QW431.1 and QW461.2

Basically there are three inclinations involved.

- Flat, which includes from 0 to 15 degrees inclination

- 15 - 80 degrees inclination

- Vertical, 80 - 90 degrees